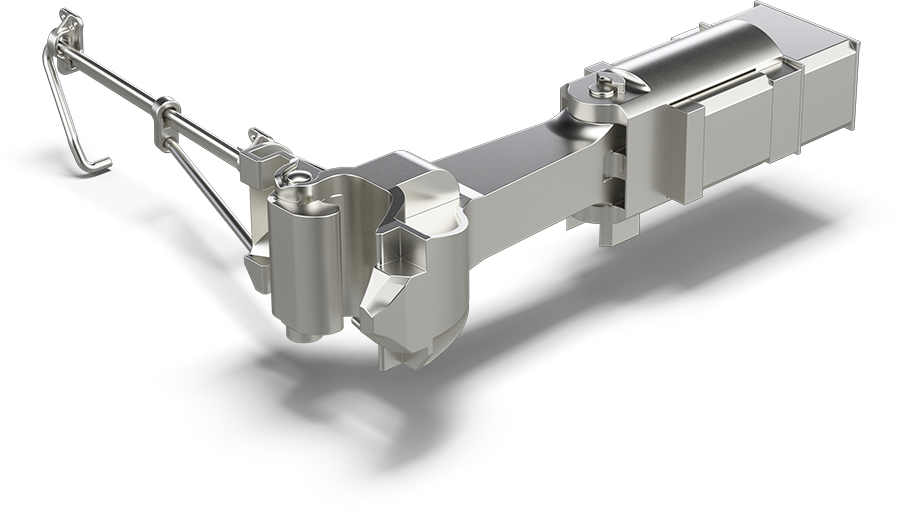

Amsted Rail is the global leader in bogie systems and end-of-car components. In the freight rail market, we continue a 100-year tradition of developing solutions that advance durability, reliability and safety. With the acquisition of service-proven General Steel Industries (GSI) product line, we’re now leveraging our performance-driven expertise to redefine what’s possible in the transit industry.

Headquartered in Chicago, Illinois, Amsted Rail designs, engineers, tests, and manufactures our entire suite of transit products in the United States. State-of-the-art facilities are spread across the USA, combining our operational expertise with a manufacturing footprint that has grown with this country’s expanding rail needs for more than a century.

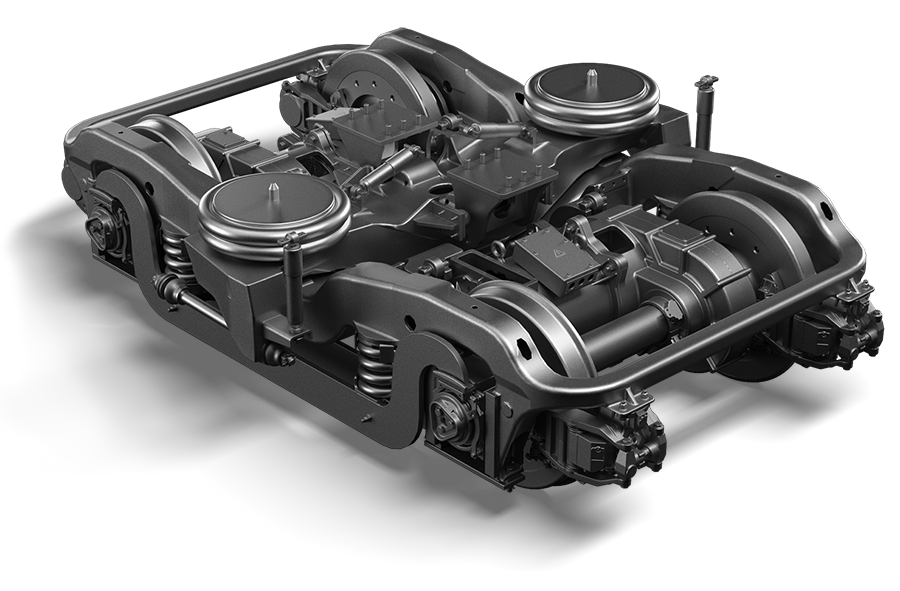

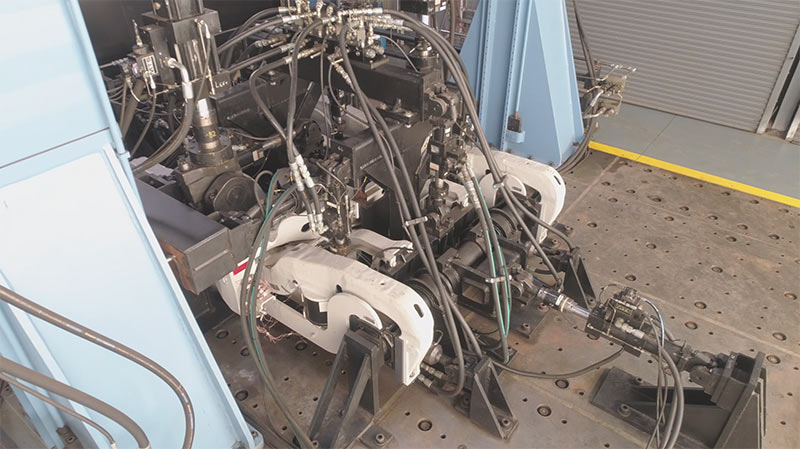

Amsted Rail is the only transit bogie manufacturer in America with both internal modeling and dynamic simulation expertise, along with in-house testing facilities to validate. Our transit division builds on Amsted Rail’s expertise in testing undercarriage and end-of-car components to meet customer specifications. Next generation machines allow us to push the envelope, subjecting complete transit bogie systems to the most rigorous testing.

In 2017, a Northeast Corridor transit agency opened a bid request for Multilevel III coaches. Collaborating with a global coach builder, Amsted Rail seized the opportunity to design, model and optimize GSI truck designs to exceed APTA, FRA, high-speed stability, and ride quality requirements. As part of its mission, Amsted Rail also sought to maximize the US content of its truck system proposal.

Amsted Rail

Amsted Rail Headquarters

311 S. Wacker Drive,

Suite 5300

Chicago, IL 60606

+1.312.922.4501